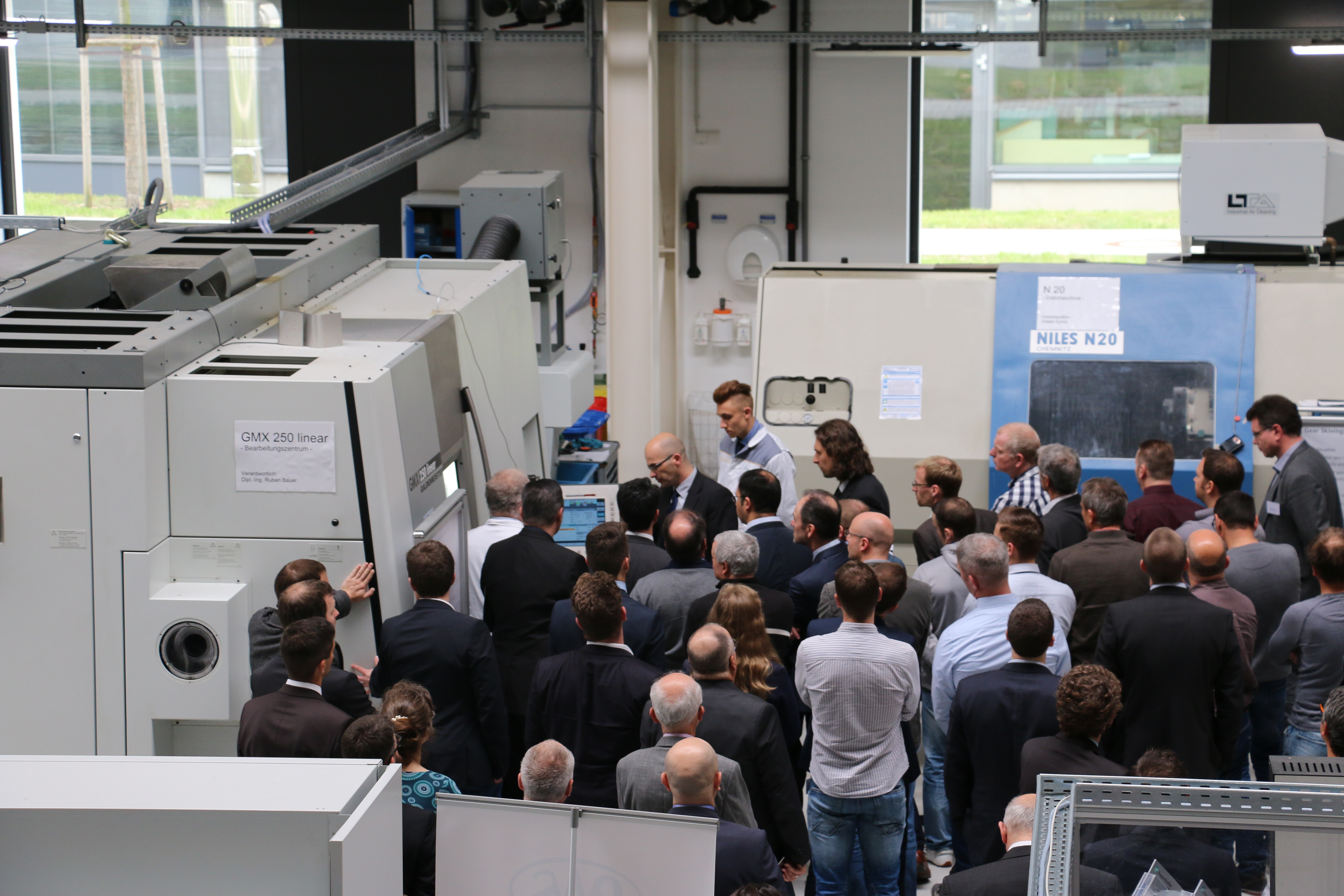

Our technical seminar has been held every two years since 2016. You can expect informative presentations from renowned speakers, as well as practical demonstrations covering all aspects of machines, tools, and processes. Together, we will discuss the latest developments and challenges in power skiving. Furthermore, you will gain valuable insights into topics such as process optimization, cutting parameters, and the reduction of setup and machining times through live demonstrations.

A key focus is the exchange of information on the current state of development and unresolved problems, allowing participants and experts to network directly. The seminar is always held in close cooperation with leading machine and tool manufacturers. Moreover, we place great emphasis on a strong practical orientation.

After five successful events, we look forward to welcoming you to the 6th technical seminar on November 27, 2025. You can register directly here: «Registration 6th Technical Seminar».

In addition to our technical seminars, we have been offering a workshop since 2021. Here, the focus is primarily on practical application, alongside the theoretical transfer of knowledge. The workshop takes place in the laboratory and utilizes small working groups, live demonstrations, and clear explanations directly on the machine. This gives you the opportunity to immediately apply what you have learned and gain valuable experience in a practical environment.

At the bottom of the page, you will find an overview of our past events in chronological order.